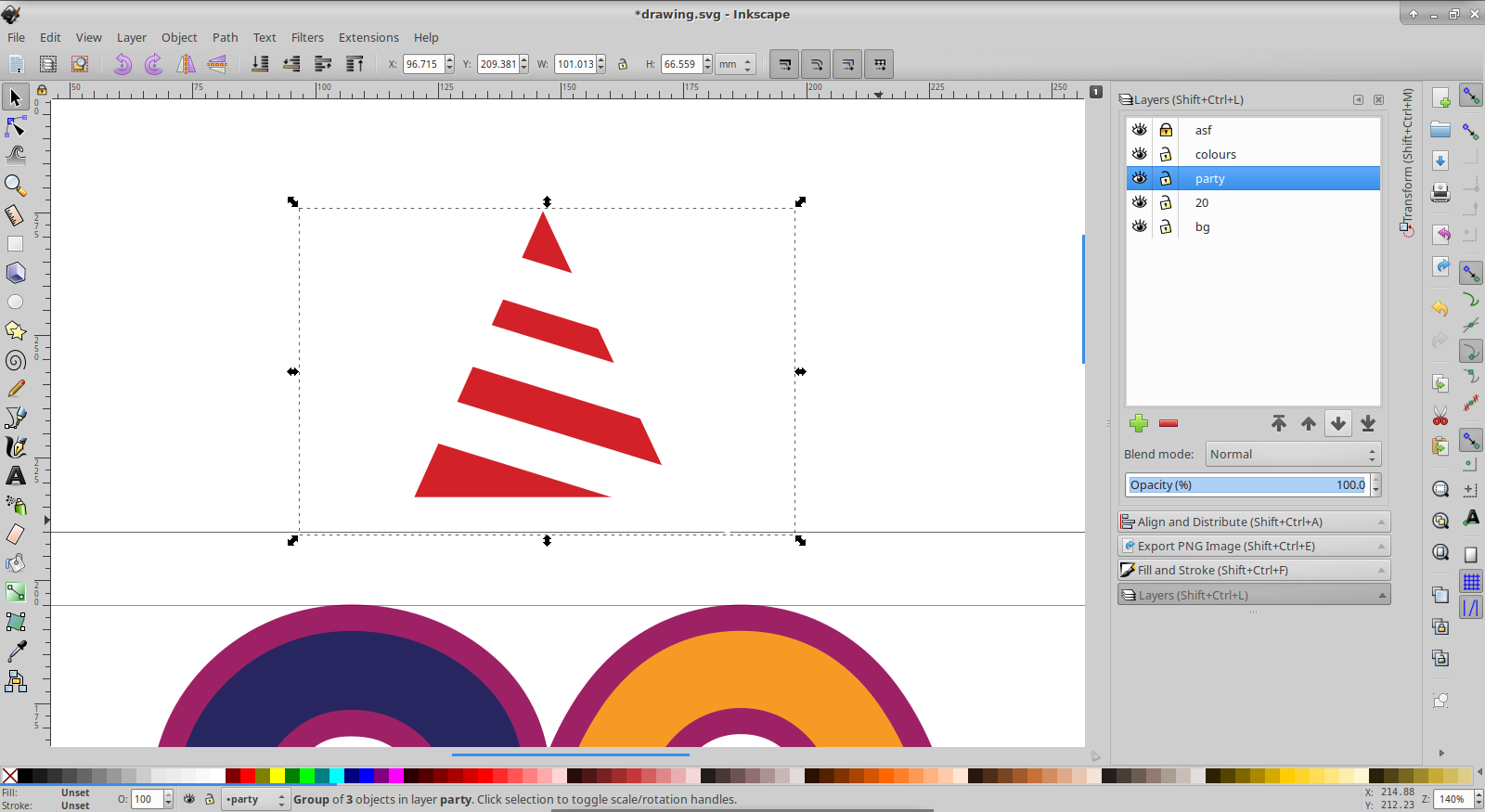

This post focuses on setting up Inkscape for the CNC machine and producing the g-code from your drawing, it is not intended to be an Inkscape tutorial. These notes are based around my cheap CNC machine sold as an CNC3018 by a variety of Chinese manufacturers on Amazon and eBay, the included controller is a Woodpecker CNC board (Ardunio clone) I have upgraded to GRBL v1.1 and I am using version 0.92.4 (April 2019) of Inkscape with the included Gcodetools. While Inkscape doesn’t have many of the functions of proper CAD/CAM software it is an relatively easy place to start for creating basic designs, I have been using it to make boxes out of 3.5mm plywood. Inkscape is a free vector graphics editor for all major platforms, generally it is aimed at art and design users but it does have an option for generating G-Code for use in your favourite CNC software.

0 kommentar(er)

0 kommentar(er)